Feature

For UV reactive paint formulations, selecting an excellent silicon dioxide (SiO2) powder involves considering properties

that contribute to both the desired UV responsiveness and overall performance of the paint. Here are some key factors to

look for:

UV Transparency: The SiO2 powder should be transparent to UV light to allow the UV reactive components in the paint

formulation to function effectively. A high level of UV transparency ensures that the paint exhibits the desired fluorescent

or phosphorescent response when exposed to UV light.

Particle Size: Fine particle size is preferable to ensure uniform dispersion in the paint formulation and avoid altering the

paint's appearance or texture. Smaller particles also contribute to improved transparency and clarity of the UV reactive

paint.

Surface Modification: Surface-treated SiO2 particles can enhance compatibility with other paint components, improve

dispersibility, and prevent agglomeration or settling in the formulation. Surface modification may also influence adhesion,

durability, and UV stability of the paint.

UV Stability: The SiO2 powder should be UV stable to prevent degradation or discoloration of the paint film when exposed

to prolonged UV radiation. UV-stabilized SiO2 particles help maintain the paint's performance and appearance over time,

especially in outdoor or high UV exposure environments.

Chemical Compatibility: Ensure that the SiO2 powder is chemically compatible with other components in the paint formulation

to prevent adverse reactions or changes in paint properties. Compatibility testing is essential to assess interactions between

SiO2 and UV reactive pigments, binders, solvents, and additives.

Dispersion Stability: The SiO2 powder should disperse easily and uniformly in the paint formulation to achieve consistent UV

responsiveness and overall coating performance. Good dispersion stability prevents issues like settling, agglomeration, or

uneven distribution of UV reactive components in the paint.

Optical Clarity: SiO2 particles should maintain the optical clarity of the paint film to ensure the UV reactive effects are visible

without interference or distortion. Optically clear SiO2 powders contribute to a visually appealing finish and enhance the visibility

of UV-induced effects.

Regulatory Compliance: Ensure that the SiO2 powder meets relevant regulatory standards and safety requirements for use

in UV reactive paint formulations, particularly concerning chemical composition, toxicity, and environmental impact.

When selecting a SiO2 powder for UV reactive paint formulations, consider consulting with suppliers for product recommendations

and conducting compatibility testing to evaluate the powder's performance in specific paint formulations. By choosing an excellent

SiO2 powder tailored to your UV reactive paint requirements, you can achieve vibrant and long-lasting UV effects while maintaining

paint performance and durability.

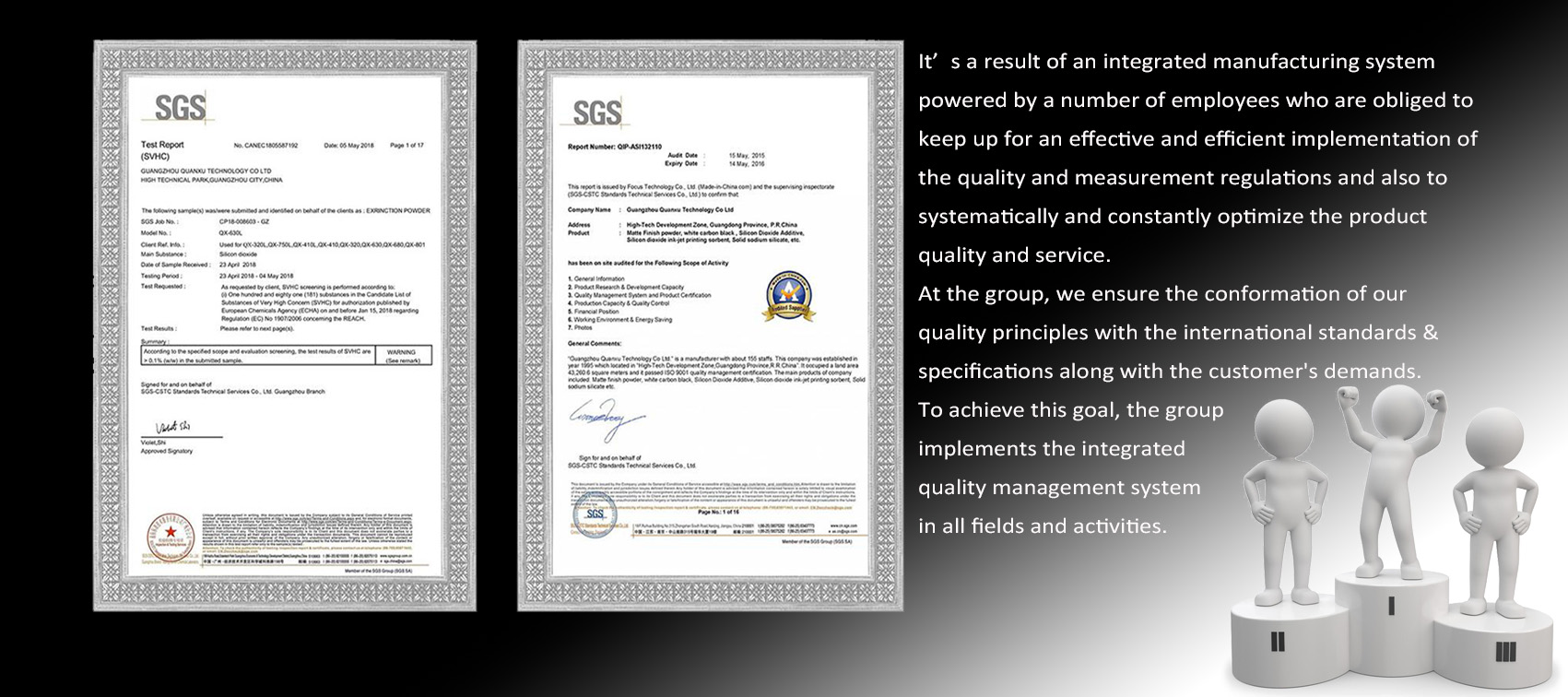

| 物品 | SS-850 | 品牌 | 天空银

|

| SiO2含量(干基)%≥ | ≥99 | 白度 | ≥90 |

| 孔隙率ml/g | ≥1.2 | 直径(马尔文特),um | 6.0-6.5 |

| 干燥失重(105 ℃ ,2小时),% | ≤6.0 | PH值 | 6.0-7.0 |

| 烧失量(1000 ℃ ,2Hrs),% | ≤13.0 | 吸油量g/100g | 130-170 |

防腐涂料, 阿富汗接受涂层, 消光剂

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent,Water-Based Canvas