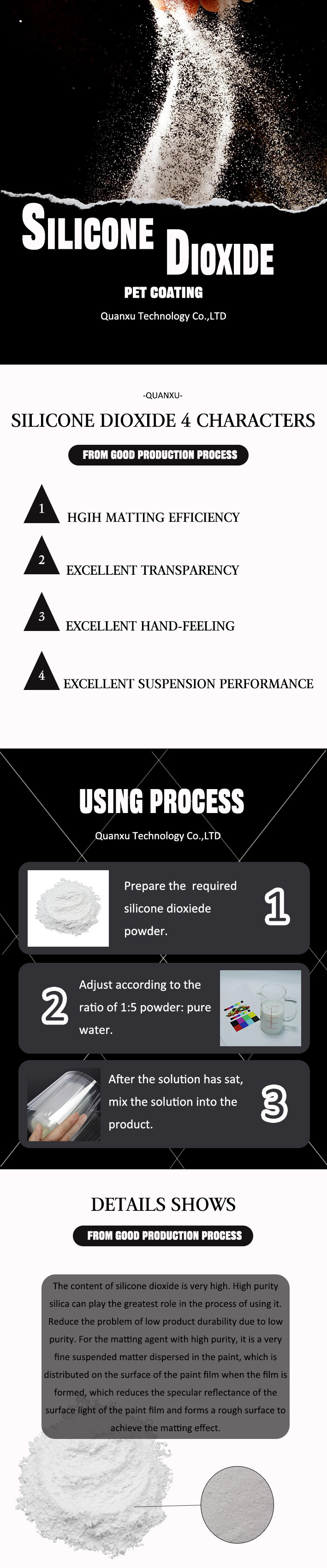

Feature

Silica dioxide is a common material used in inkjet receptive coatings. It is a form of silicon dioxide, which is a compound

made up of silicon and oxygen atoms. Silica dioxide is known for its high transparency, hardness, and chemical stability.

In inkjet receptive coatings, silica dioxide is used as a filler or a binder to enhance the coating's properties. It helps to improve

the coating's smoothness, absorbency, and ink adhesion. Silica dioxide particles have a large surface area, which allows them

to absorb and hold ink droplets effectively.

The use of silica dioxide in inkjet receptive coatings also helps to prevent ink bleed and smudging. It creates a porous structure

that allows the ink to penetrate and dry quickly, resulting in sharp and vibrant prints. Additionally, silica dioxide can contribute to

the coating's scratch resistance and durability.

Silica dioxide is often combined with other materials such as polymers, binders, and additives to create a well-balanced inkjet

receptive coating. The amount and particle size of silica dioxide used can vary depending on the desired coating properties and

the specific application requirements.

Overall, silica dioxide is a crucial material in inkjet receptive coatings as it plays a significant role in improving print quality, ink

adhesion, and coating durability.

| Appearance | Milk White solution |

| Solid Content | 35±1% |

| PH Value | 6-8 |

| Viscosity | 2800-3500 mpa.s |

| Stability | Six months |

Anticorrosion Pigments,

Inkjet Receptive Coating,

Matting Agent